Technology

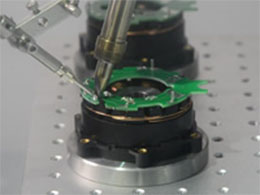

1Clicksmt automatic soldering robot is equipped with 400W high frequency heating system with rapid heat recovery. Induction type soldering tip heating speed is very fast. Break-tin automatic solder wire feeder can reduce flux remaining problem after soldering.Both of them can make the stable soldering quality.

- Home

- Technology

Stable soldering quality

Soldering for retrofit parts has problems such as solder bridging, solder ball spattering and cold solder so that stabilizing of soldering quality is difficult.

The reason for this phenomenon is !

There are many factors making soldering to be difficult as following:

Differences in workers’ skills Differences in parts quality.

There are many factors making soldering to be difficult as following:

Worn out of soldering tip Unstable heat supply Unstable solder amount.

To solve these problems, 1CLICKSMT Automated Point Soldering Robot System.

We have successfully managed to stabilize the three unstable factors:

solder amount

by our unique system.

Especially, we stabilize necessary heat amount for soldering and this is our goal for “standardization of soldering quality.”

heat supply

by our unique system.

Especially, we stabilize necessary heat amount for soldering and this is our goal for “standardization of soldering quality.”

soldering tip shape

by our unique system.

Especially, we stabilize necessary heat amount for soldering and this is our goal for “standardization of soldering quality.”

The way to ensure stable soldering quality

Stabilization Technology of Solder Amount

If solder Amount is not steady, soldering will be difficult because the heat to melt solder and the heat to be transferred to parts will be changed.

The “400W high frequency induction heating system+Accurate break tin solder wire feeder +soldering” system of the automatic soldering robot H351 has solved it as follows.

[Learn more]

Many Advantages by Stable Solder Amount

Highly Accurate, Continuous Stability.

Solder wire feeding accuracy can reach 0.1mm to ensure the stability and accuracy of the amount of tin per solder joint.

Far less frequency of solder balling and flux spattering.

Break tin solder wire feeding system can pierce holes when feeding solder wire, it can reduce burst tin that causes flux remaining on PCB when soldering under high temperature to improve the soldering quality.

Stable Heat Supply Technology

About Soldering with 400W high frequency induction heating system has rapid temperature recovery time, heating element adopt silver coil which can ensure long lifetime.

Optional With 600W high frequency heating system with rapid heat recovery. For solder joints that absorb a large amount of heat, heat can be quickly transferred to the pads and pins, heat concentration, ensure high soldering quality.

[Learn more]

Induction soldering tip

Heating element adopt silver coil which can ensure long lifetime. Induction type soldering tip can be easily changed with lower cost. The welding head and the heating core are independent individuals.

[Learn more]

Solder wire feeder

Break tin solder wire feeding system can pierce holes when feeding solder wire, it can reduce burst tin that causes flux remaining on PCB when soldering under high temperature to improve the soldering quality. solder wire feeding accuracy can reach 0.1mm, equipped with Lack tin and block tin automatic check function.

Copyright © 2023. 1clicksmt-solderingrobot. All Rights Reserved